Overhead Conveyors Types, how they work, benefits and uses

Overhead Chain conveyor Systems china Overhead Conveyor Chain and Parts manufacturer

Overhead Conveyor Definition of Terms. A continuous circuit of chain running through track and a variety of vertical and horizontal curves. A Drive unit that grabs the chain and pull it through the track. A Take-up unit that ensures the chain is always stretched tight, even as it wears over many years of use. Electrical controls which may be a.

Overhead Chain driver systems Conveyor, Conveyor system, Overhead

Roller Track Sets for Bypassing Cabinet Doors. For smoother operation, these sets include upper and lower roller track for hanging lightweight cabinet doors that slide past each other. Choose from our selection of overhead conveyors, including trolley chain, trolleys, and more. In stock and ready to ship.

Best Selling Fu Type Overhead Chain Conveyor Price Buy Fu Type Chain Conveyor,Overhead

The Original Bridgeveyor™ Overhead Conveyor System Home / Systems Why Choose The Bridgeveyor™ C-250™? It's a Smart Investment From small workshops to the largest manufacturing and warehousing facilities, you need to know that the overhead conveyor chain system you choose makes the most sense for your business goals and bottom line.

Overhead Conveyor Chain, Overhead Conveyor Chains Ghukna, Ghaziabad S. K. Conveyor System

Overhead conveyor systems, design, and high-performance chain from Richards-Wilcox increase efficiency and automate processes for your company. Call today!

Optieng Overhead Conveyor Systems

8. Select horizontal curve radius. (Curves 24" radius or larger will reduce chain pull) 9. Verify all clearances, both horizontal and vertical. 10. Select tentative track elevations with respect to the bottom of the track. 11. Draw overhead conveyor layout to the largest possible scale.

Overhead Chain Conveyor【厂家 设备 定制】Anyang Zheng Cheng Machinery Co., Ltd.

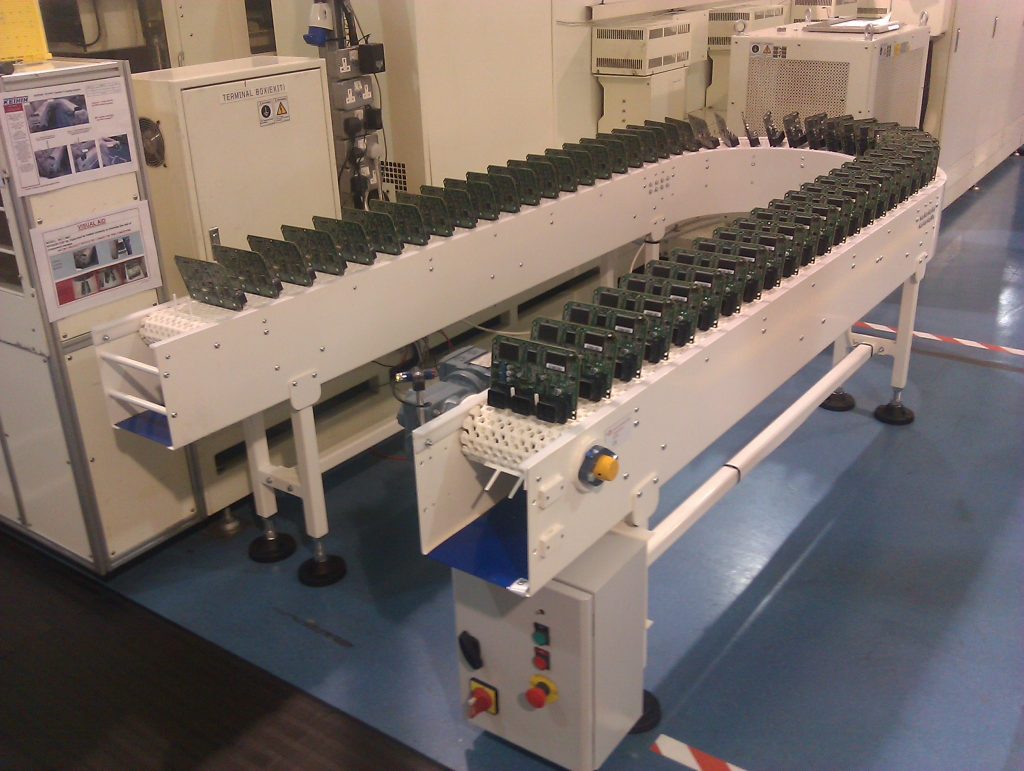

The overhead chain conveyor is a cost-effective solution wherever large quantities of material to be transported are to be transported at a constant speed. The classic system of overhead conveyor technology is particularly suitable for use in extreme environmental conditions and in enclosed spaces.

Powder Coating Overhead Conveyor Chain Types Buy overhead conveyor chain, Overhead Conveyor

Overhead Conveyors are of three basic types: Free Systems with hand pushed trolleys available with a complete line of curves, brackets, switches, turntables, crossovers, lowerators, etc Power Systems with chain, drive (s) and a complete line of horizontal and vertical curves, take-ups, attachments, load bars, safety devices, etc

Overhead Conveyors Types, how they work, benefits and uses

Track Trolley Weight Capacity 125 lb. 200 lb. 250 lb. 400 lb. 500 lb. 1,500 lb. Material Iron Steel For Track Height 3" 3" to 4" 4" 4" to 6" Height 1 1/2" 2 3/4" 3" 4" 4 1/4" 4 7/16" 4 1/2" 4 15/16" 5 5/8" 6 1/16"

Powered overhead conveyors LB Foster

Take-up sections allow for chain oiling, stretch maintenance and tension; Simple machines with 99.9% uptime; Benefits of overhead trolly conveyor. The benefits of overhead conveyors are vast but are also dependent on a specific operation. Reduces forklift traffic, labor, floorspace, and machines; Allows for easy inspection of production line goods

Overhead Conveyor Systems at Rs 1087.48/piece New Alipore Kolkata ID 3565771230

Overhead Conveyor Chain Frost supplies X-Type overhead conveyor chain in 3″, 4″ and 6″ I beam applications. Our chains can be purchased in standard steel, high alloy steel and stainless steel material according to customer requirement and satisfaction.

MS Overhead Chain Conveyor, Capacity 500 To 1000 Kg/H, Rs 400000 /piece ID 21264513748

An overhead conveyor chain is a continuous track suspended on an overhead support that can carry a variety of items. These chains can be customized to carry a variety of materials and free up floor space. Overhead conveyors are a cost-effective way of transporting and sorting goods in factories.

China Overhead Chain Conveyor System (load bar, chain, trolley, trolley carrier) China Chain

Overhead conveyors are unique from other conveyor types in that they operate above - or over - the head of both workers and other equipment. They maximize conveyance by utilizing unused overhead space, and do so via a revolving, endless loop of chain within a rigid track, or a straight run of trollies.

Silver And Blue Mild Steel Overhead Chain Conveyor, Capacity 100150 kg per feet, Automation

Overhead conveyors are what people are generally thinking about when they hear the word "conveyor". One of the most common types of conveyor, an overhead conveyor is generally used in a production facility to move parts from one location to another. They take advantage of the generally unused vertical space above the working area.

Automatic Stainless Steel Overhead Chain Conveyor, Length 4060 feet at Rs 1500000/unit in Kolkata

Overhead chain conveyors stand out as the epitome of efficiency and convenience in material handling for surface coating plants. The impact of a meticulously designed conveyor system, coupled with a well-considered layout, cannot be overstated in enhancing the overall efficiency of a surface coating plant. Factors such as the production rate.

Overhead Chain Conveyors Prestige Conveyors Ltd

The PAC-LINE™ is a medium-capacity, enclosed track overhead monorail conveyor designed for maximum conveying flexibility in small spaces. 50 lbs. per pendant. Cross Track Conveyor The PAC-MAX™ is a heavy-duty enclosed track conveyor that features a unique cross "+" shaped track for exceptional load stability. 220 lbs. per trolley.

Overhead Chain conveyor Systems china Conveyors Systems manufacturer Hangzhou Color Powder

Overhead monorail chain conveyor. CONVOYNORT's overhead monorail chain conveyor forms a closed loop. From small carousel to long circuit including level differences, CONVOYNORT's chain conveyor will bring you advantages that are described below.. Work pieces or carried loads hang on conveyor chain directly or by intermediate supports as load bars, carriers, rotation devices, hooks, links, etc.