5S Lean Methodology & Principles [Lean Manufacturing]

5S Training Poster Ribbon SKU11637 The Lean Centre

Introduction Equipment The Deal The Play Scoring Comments and Strategy Variations Other Fives and Threes web pages Introduction This game is a member of the Fives family, in which points are scored for making the ends of the layout add up to certain totals, in this case multiples of 3 and 5.

Lean Laboratory 5S for the Laboratory

Setup. Shuffle the dominoes, face-down, on the table. Each player draws the appropriate number of dominoes (see below) and stands them on edge so that they can see the faces (the side with the pips) but their opponents cannot. With 2 players, each takes 9 dominoes. With 3 players, each takes 7. With 4 players, each takes 5.

5S Signs Creative Safety Supply

In england the game of 5's and 3's is a serious game,played in pubs and clubs around the country.It is normally played 2v2 players. The object is to score 61 points exactly,scoring points for dominoes that divide by 5 or 3. To score players count

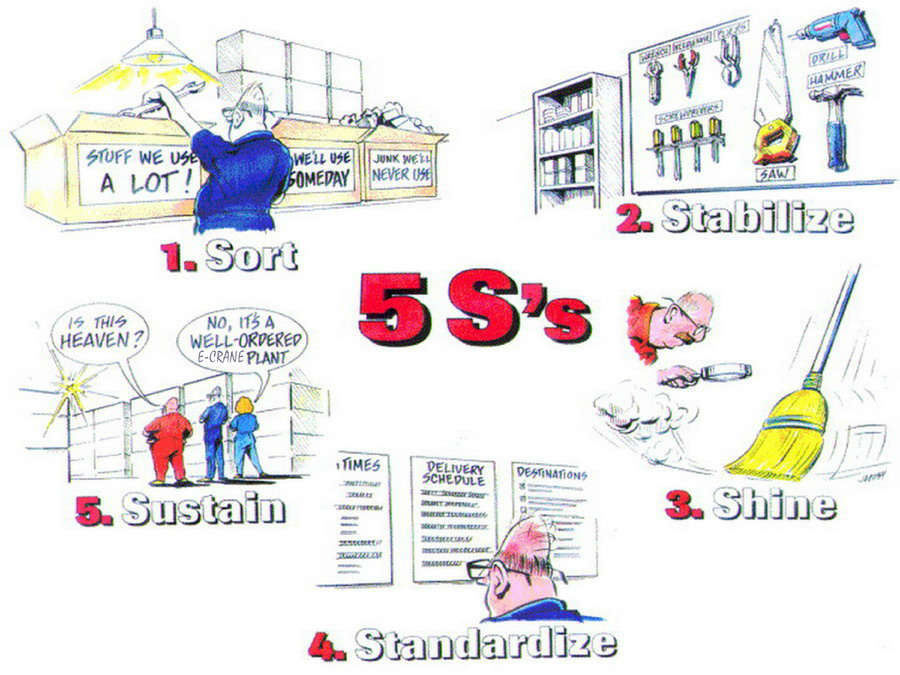

5S method implemented by ECrane Worldwide ECrane

For example, if the layout's open ends total 6 (3 x 2 = 6) they score 6 points; if the open ends total 10 (5 x 2 = 10) they score 10 points; if the open ends total 30 (3 x 10 = 30 and 5 x 6 = 30) they score 60 (30 + 30). Players scores are recorded on the score-sheet as play progresses. Once a player has dominoed by setting their last tile, or.

Lean 5S Six Sigma Safety Science

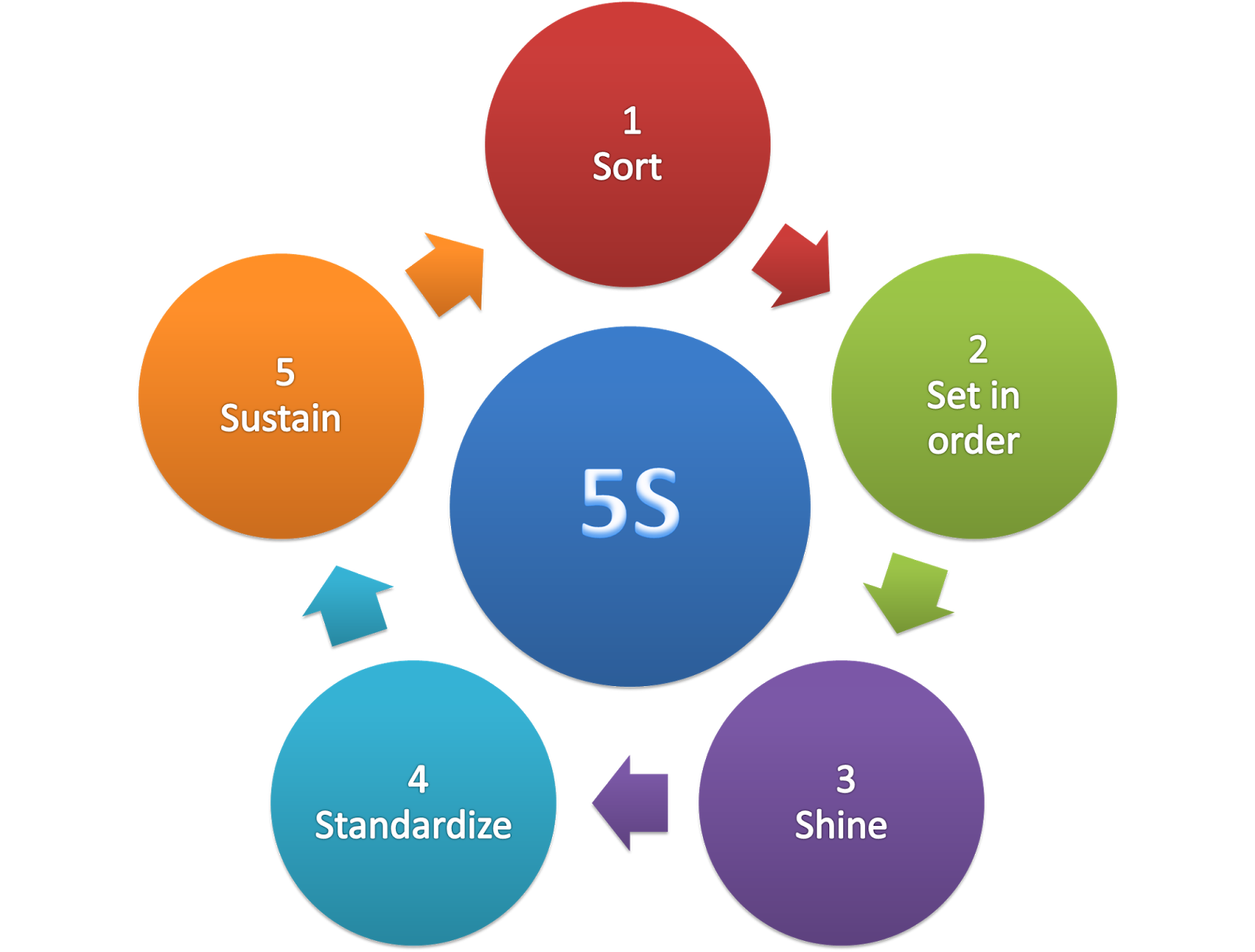

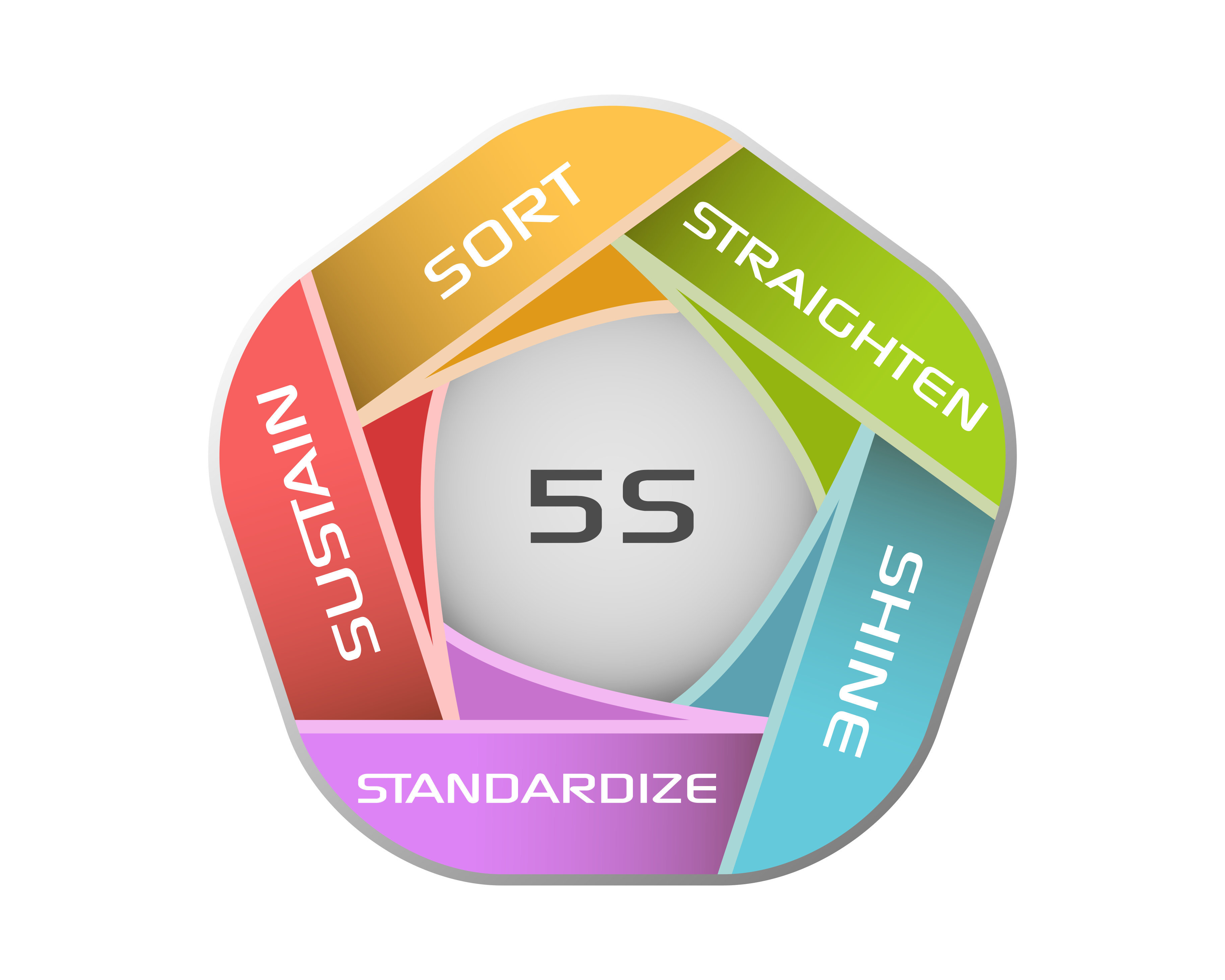

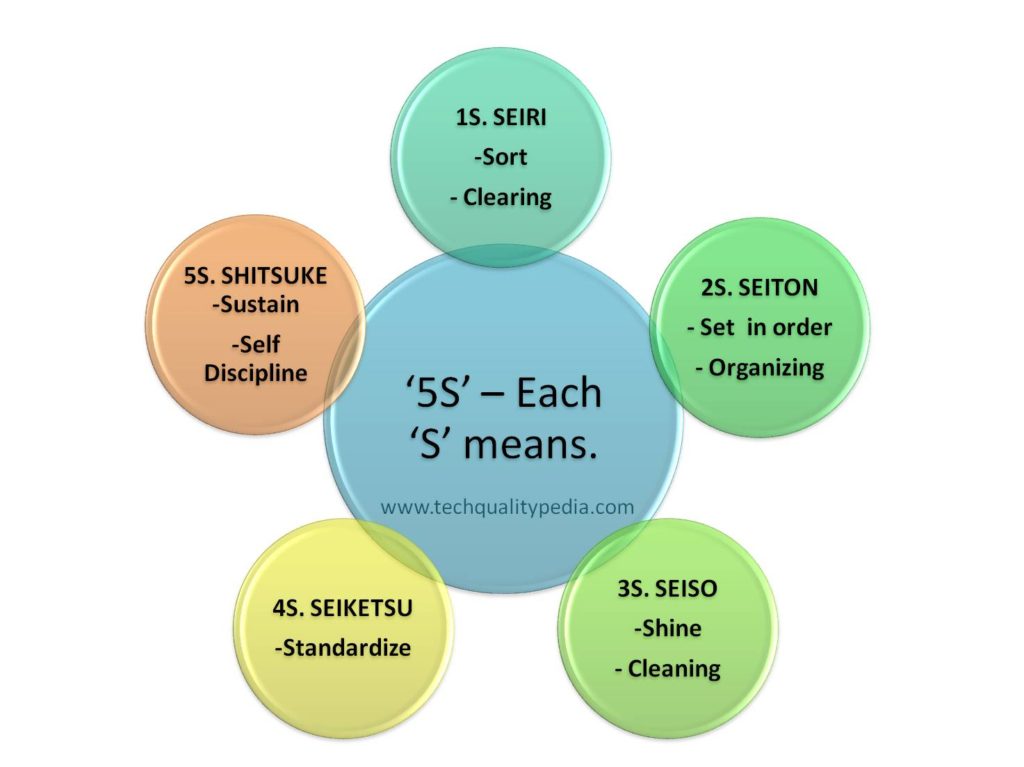

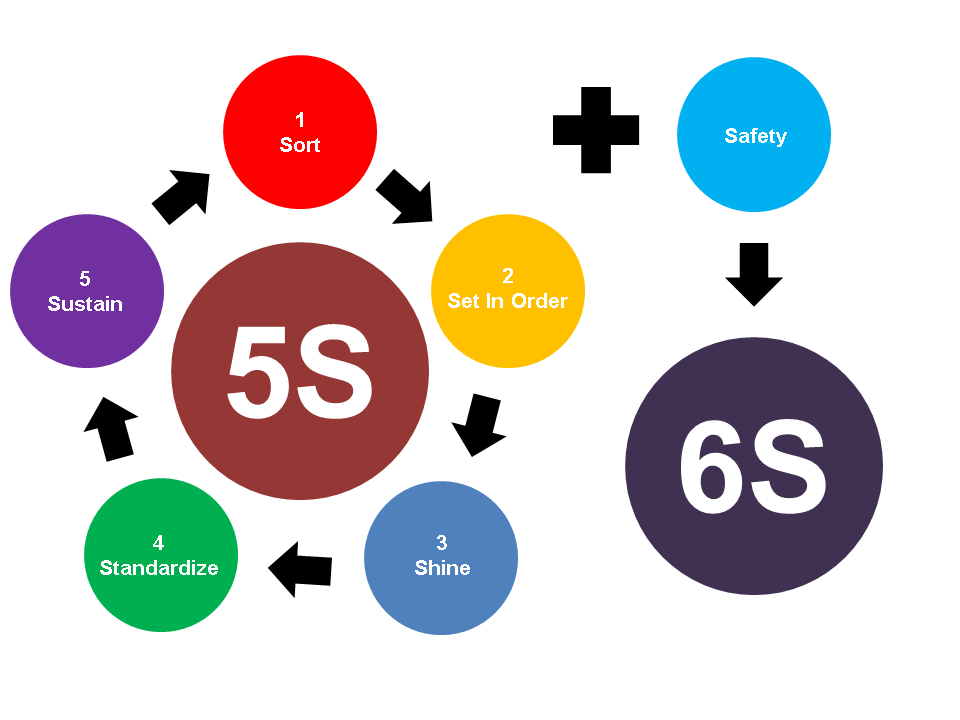

5S is a workplace organization method that uses a list of five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). These have been translated as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. [1]

What is 5S? 5S System is explained including tips on getting a 5S program started.

Threes and Fives Domino Basics Number of Players: 2 - 4 Type of Dominoes Used: Double 6 Type of Game: Scoring Game What's unique: A player is awarded points every time he makes a play that results in the open ends of the tiles in the line of play adding up to a multiple of 3 or a multiple of 5.

5S Lean 5S Principles in the Workplace SafetyCulture

5S is a systematic way of organizing workplaces by eliminating waste, improving flow, and reducing the number of processes where possible. It applies the five principles: Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke). These principles were pioneered by Toyota Motor Company and has improved.

What is 5S ? Why is it so effective

What are the Principles of 5s? 5s is a philosophy applied in the workplace that helps promote efficiency and effectiveness. As one of the core principles of kaizen, 5S lean principles can help identify and eliminate wastage to achieve a well organized and safe working environment.

What Are The Benefits Of 5s

Tips on how to play a variation of dominoe's using your maths skills

5S Workplace Organization What is 5S and its benefits

What is 3S? Simplified methodology popularized by Paul Akers and the 2 second lean movement. Akers is hotly against 5S, which creates some confusion. But does FastCap sort, organize, clean, and have routines and disciple?

5S活動とは?3Sとは?経営者が知るべきその意味と人材育成効果 5S活動ラボ

Implementation of a visual workplace is a way to attain the common goals of Lean Six Sigma, such as reducing the 8 wastes and improving quality. The visual workplace that 5S methodology is meant to enable has roots going back centuries. However, the current form is usually considered to have been part of the evolution of the Toyota Production.

Implementing 5S Methodology Across Our Depot Network

It's a simplified version of 5S. 5S stands for Sort, Straighten, Sweep, Standardize, and Sustain. 3S is just three of these: Sort, Sweep, and Standardize. Sort Sort means to get rid of all unnecessary items. Companies either sell them, recycle them, or throw them away. And the best companies do this on an ongoing basis.

5S We provide the equipment to implement it effectively

Tip #1: To help sustain 5S practices, make sure all new employees.

Lean Manufacturing Concepts 5S System A place for everything & safe working place

5S is 3S It's generally clean and tidy, but there's difficulty in standardizing so we keep falling back 5S state - how to stay on this level 5S has been applied in the workplace, but there is difficulty with sustaining and securing it 5S on a high level - securing can be more efficient

5S Lean Methodology & Principles [Lean Manufacturing]

Fives and Threes Dominoes AlgoTech Contains ads 4.5 star 98 reviews 5K+ Downloads Everyone info Install About this game arrow_forward In Fives and Threes Dominoes game, players score in each turn.

What is 5S and Why is it Important?

5s and 3s. Last but by no means least, players looking to add a whole new challenge to their dominoes game should try 5s and 3s. In this version, the goal is to be the first player to reach a predetermined number of points. This is usually 61, though many also play the "first to 251 rule."