How Does A 3 Phase Brushless Dc Motor Work

Brushless DC motor controller using Arduino and IR2101 Simple Projects

It works between Input voltage range of 1.65 to 5.5 V. It has very advanced features like Lock detection, Voltage surge protection, UVLO, Thermal shutdown, etc. Brushless DC Motor Driver Circuit The circuit diagram for Brushless DC (BLDC) Motor Driver using 555 IC & DRV10866 driver IC is given below.

Barry Kavramak yürüyen merdiven arduino bldc motor control

Découvrez des moteurs DC brushless robustes et sans maintenance pour votre entreprise! Servomoteur compact hautement intégré avec interface Profinet

Why do brushless motors have 3 wires compared to 2 wires on a brushed motor? Drones and Model

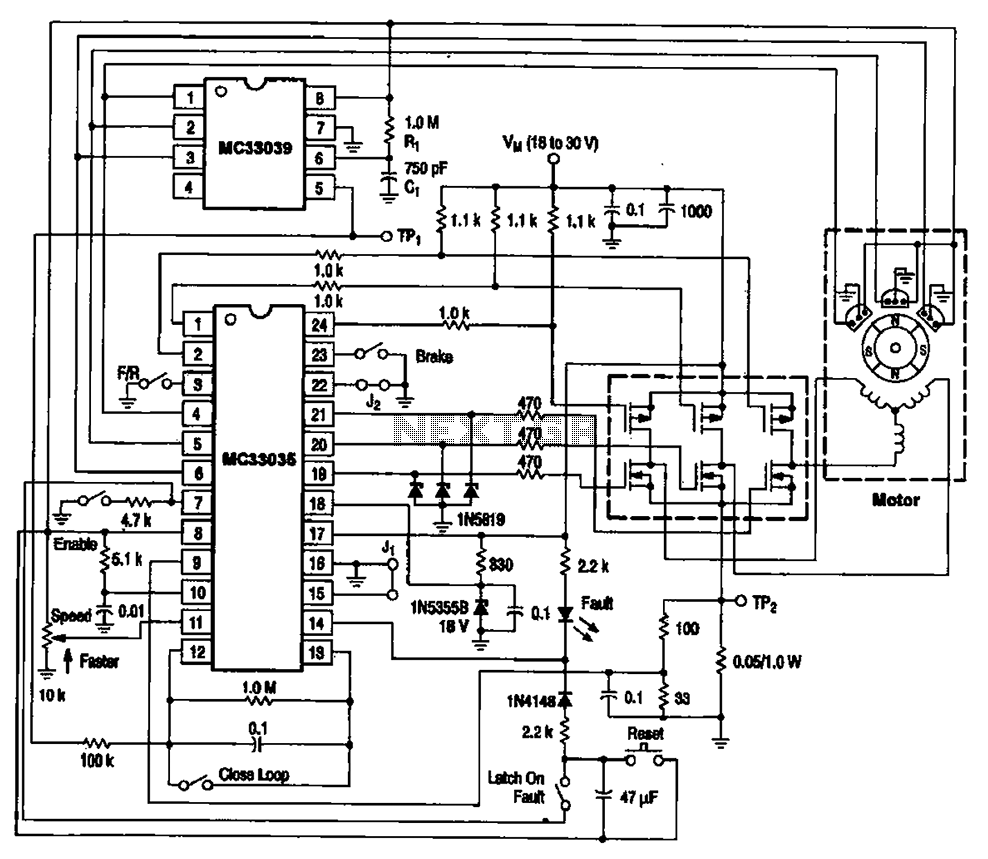

AN857 INTRODUCTION This application note discu sses the steps of developing several controllers for brushless motors. Covered are sensored, sensorless, open-loop, and closed-loop design. There is even a controller with independent voltage and speed controls so you can discover your motor's characteristics empirically.

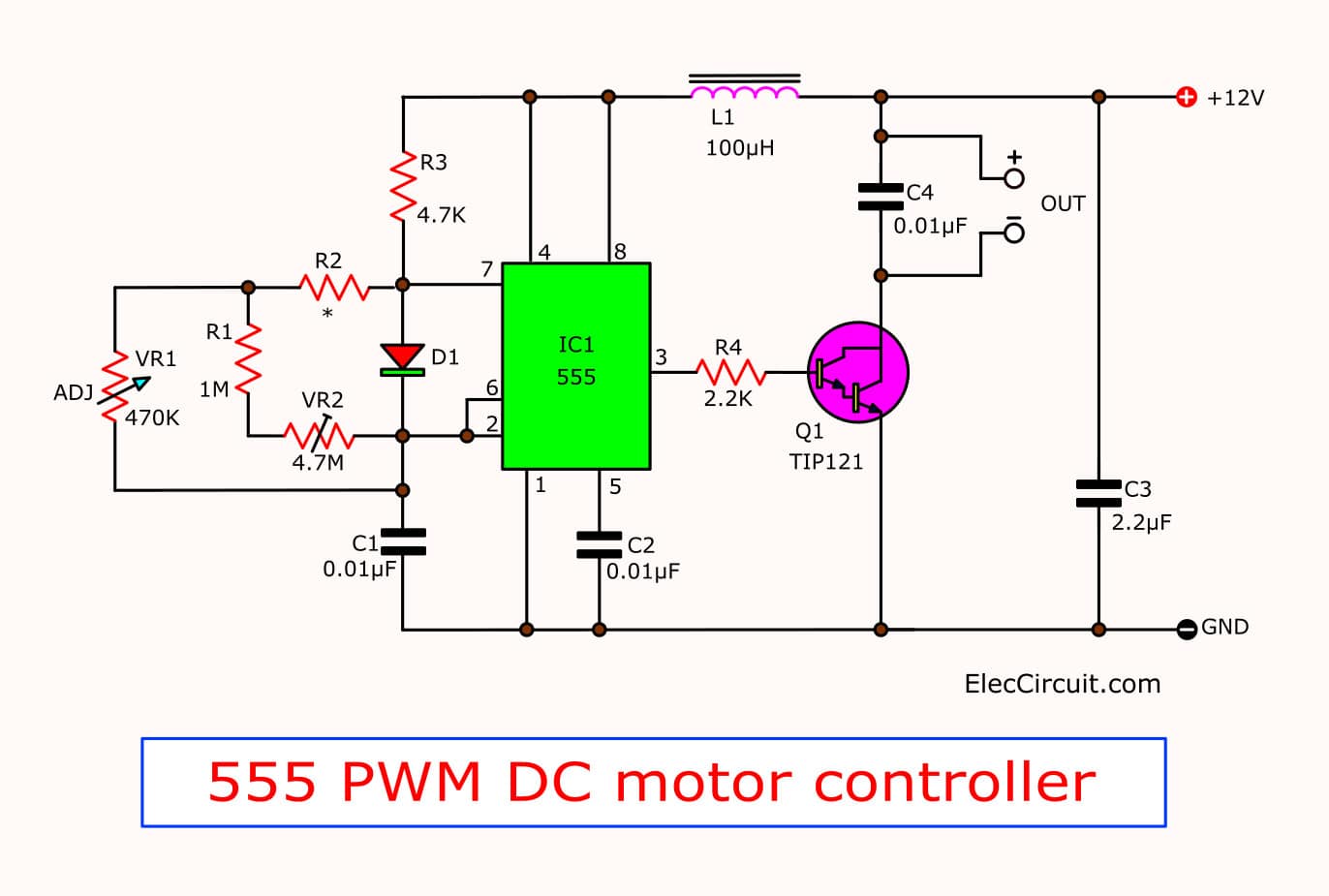

[DIAGRAM] Dc Motor Controller Schematic Diagram

See how to build the model used in this video using Simscape Electrical: https://www.youtube.com/watch?v=JDgvBZbnfPwThe model used in this video is available.

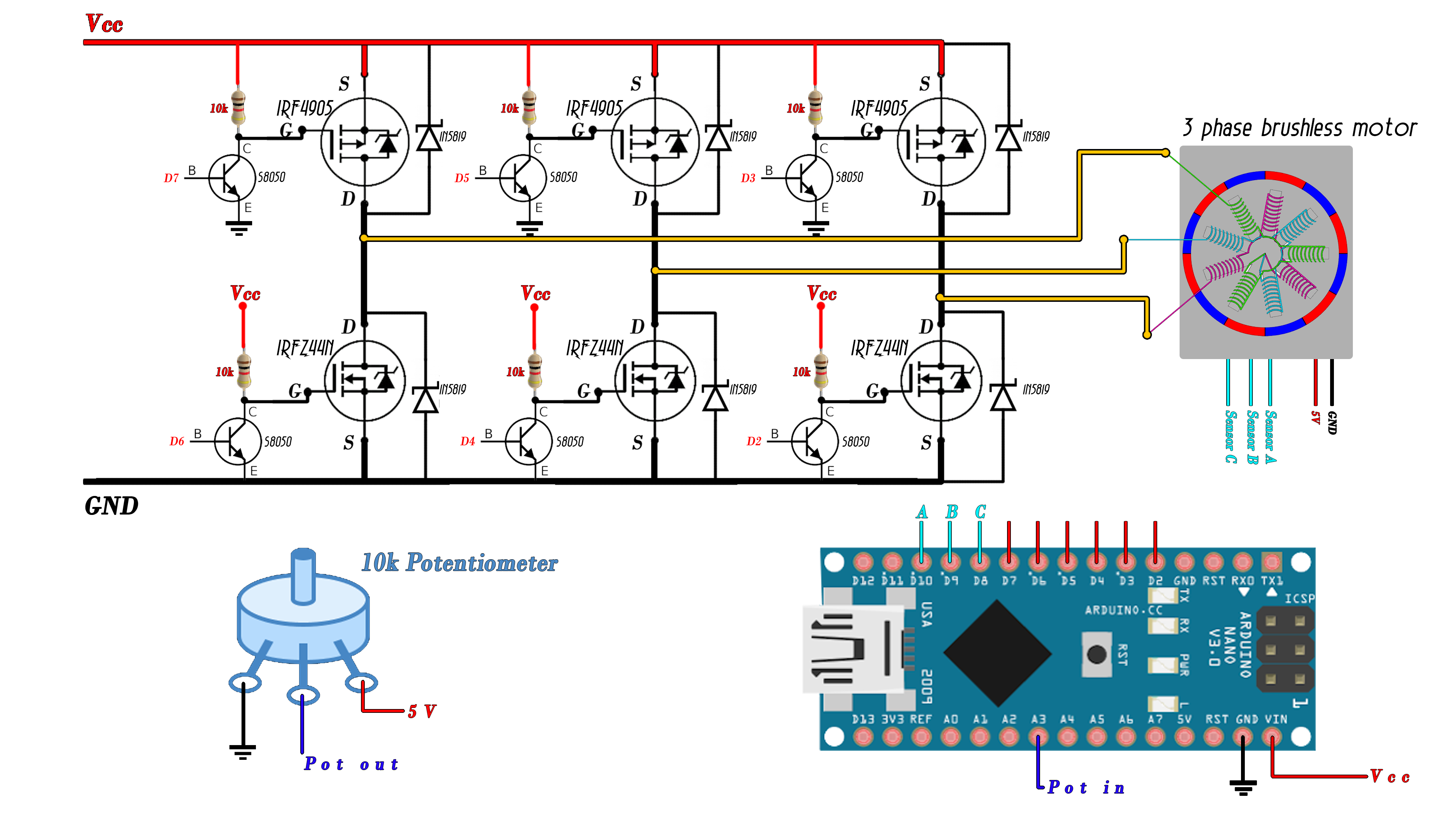

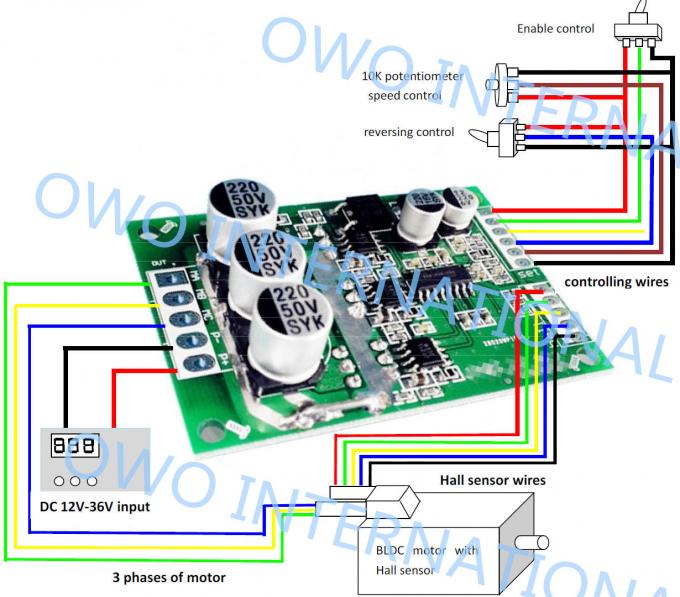

diy brushless motor controller

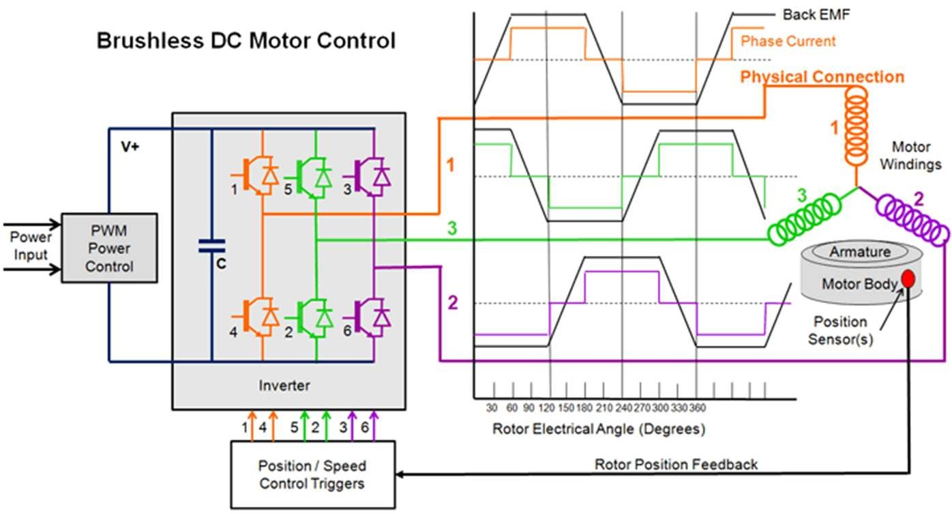

All motors require drive circuitry which controls the current flow through the motor windings. This includes the direction and magnitude of the current flow. The simplest type of motor, to drive, is the Brushed DC motor. Drive circuits for this type of motor are shown below. FIGURE 1-1: HIGH SIDE DRIVE PICmicro® Microcontroller Digital output

brushless controller schematic « Brushless motors, 3Phase inverters, schematics

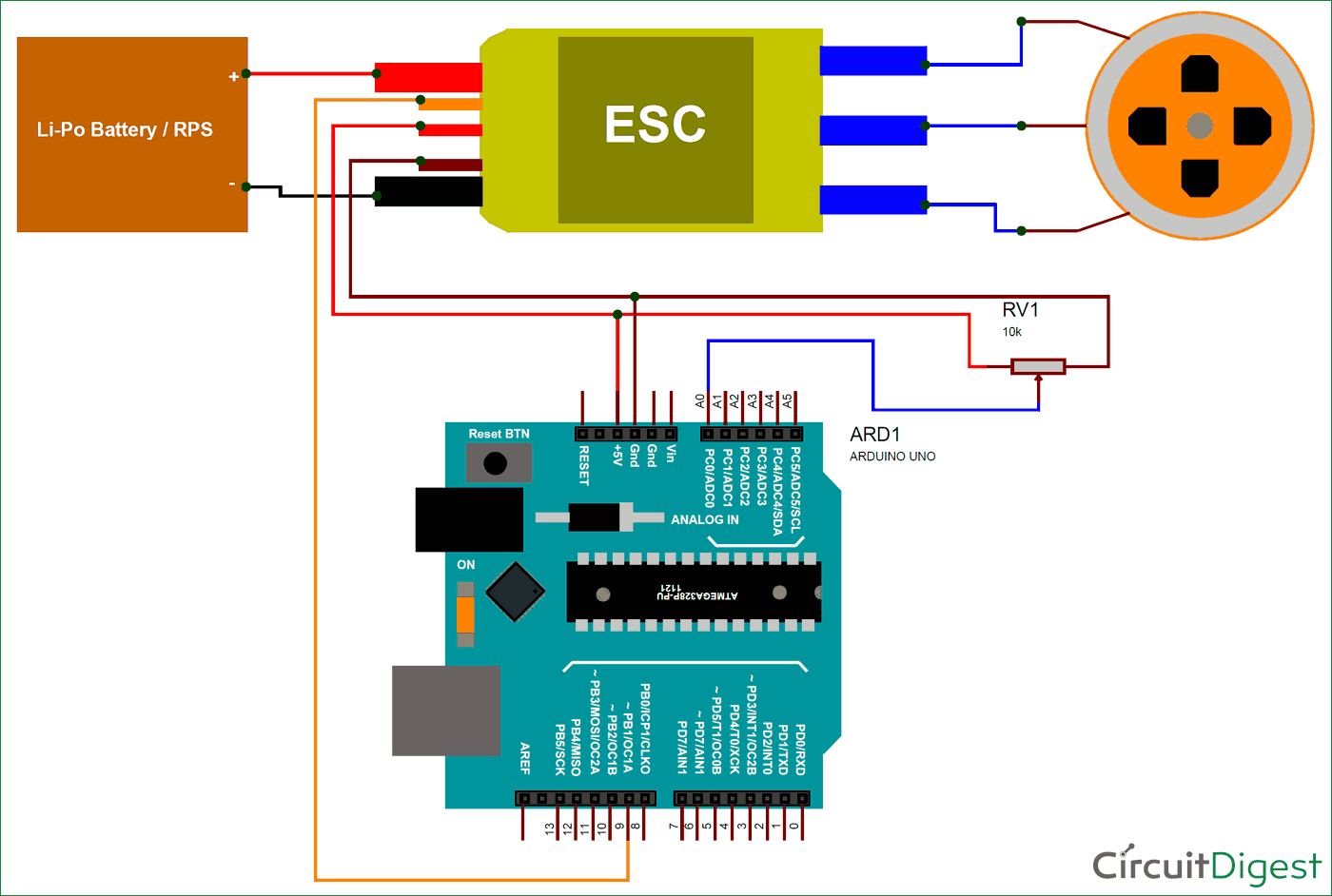

Overview For this example, I have an outrunner BLDC motor with the following specifications: it has a KV rating of 1000, it can be powered using 2S, 3S or 4S LiPo battery and it requires 30A ESC. The KV rating on a brushless motor defines the RPM of the motor per volt with no load.

Bldc Motor Controller Circuit Diagram Wiring Diagram and Schematic Role

A brushless DC electric motor ( BLDC ), also known as an electronically commutated motor, is a synchronous motor using a direct current (DC) electric power supply. It uses an electronic controller to switch DC currents to the motor windings producing magnetic fields that effectively rotate in space and which the permanent magnet rotor follows.

555 PWM DC motor controller circuit

Brushless-dc (BLDC) motors have best-in-class torque to weight ratio, high efficiency, and effective control algorithms, which make them effective solutions in applications requiring high power density, such as cordless power and garden tools, unmanned aerial vehicles (UAV), robotics, and others. Improvements in semiconductor packaging technology, motor control algorithms, and power management.

BLDC Motor Controller Schematic

Sensorless brushless DC motor control with Arduino circuit: Project circuit schematic is shown below. Note that all grounded terminals are connected together. In the circuit there are 2 pushbuttons, one is used to increase BLDC motor speed and the 2nd one is used to decrease it.

Brushless Dc Motor Controller Circuit Diagram

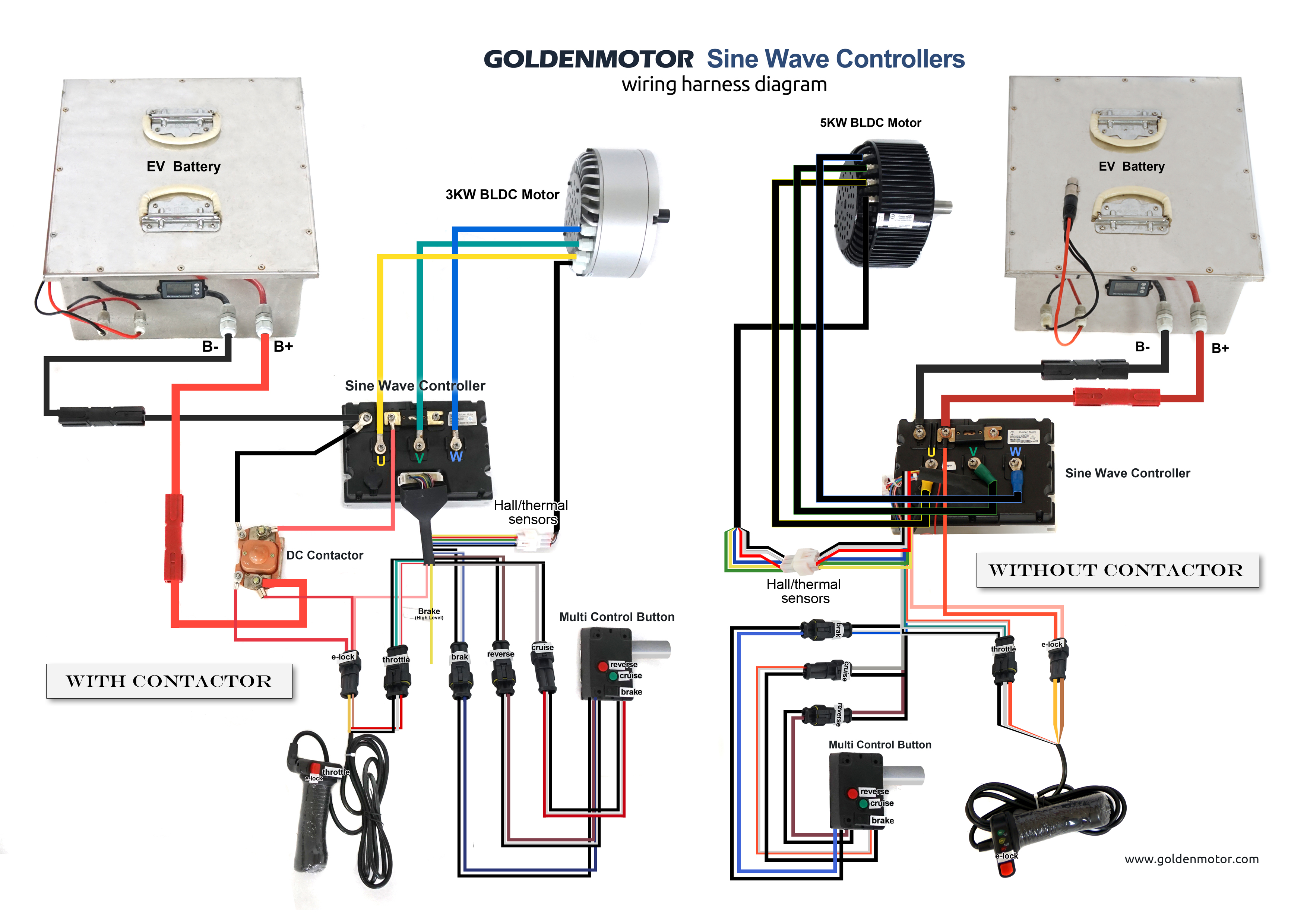

Another type to consider is the BLDC, which stands for Brushless DC motor. As the name suggests, these motors operate without brushes.. Power Supply: A source of electrical power for driving the motor and control circuits. It must match the motor's voltage and current requirements and provide a stable voltage and current without.

Sensorless Brushless Motor Controller DC 24V/36V 250W 6FET 15A KT Squ TorqueTech

How ESC Works (Electronic Speed Controller) An ESC or an Electronic Speed Controller controls the brushless motor movement or speed by activating the appropriate MOSFETs to create the rotating magnetic field so that the motor rotates. The higher the frequency or the quicker the ESC goes through the 6 intervals, the higher the speed of the motor.

CDROM Sensored BLDC motor control with Arduino Simple Circuit

This article shows how users can control a 3-phase brushless DC motor using an SLG46620 GreenPAK CMIC and Hall effect sensors. The SLG46620 also contains other features that can be used for this project. For example, the ADC within the GreenPAK can interpret an input DC voltage and generate a PWM pulse from the value, rather than using an input.

12V 15A 500W Brushless DC Motor Driver With IC , Bldc Motor Driver Board,JYQDV7.3E2

A PWM input can control the motor speed to achieve the desired motor speed. The 'FR' input allows changing the motor direction at start-up, and the 'FG' output provides motor speed information. Figure 5. The functional block diagram of the TI DRV10963 5 V three-phase sensorless BLDC motor driver (Source: TI).

Sensorless brushless DC motor drive with an ESC and PIC16F887

The brushless DC (BLDC) motor is becoming increasingly popular in sectors such as automotive (particularly electric vehicles (EV)), HVAC, white goods and industrial because it does away with the mechanical commutator used in traditional motors, replacing it with an electronic device that improves the reliability and durability of the unit.

BLDC ( BRUSHLESS DC ) MOTOR EVERYTHING YOU NEED TO KNOW

In a BDC motor, this is a mechanical process triggered by a commutator with brushes. In a BLDC motor, it happens electronically with the help of transistor switches. BLDC motor working principle

Homemade Esc Circuit Diagram For Brushless Motor

Brushless DC (BLDC) motors have become extremely popular over their predecessor, the brushed DC motor (see figure below). As the name implies, "brushed" DC motors use brushes, and a commutator, for controlling the movement of the motor's rotor. Figure 1. Brushed DC motors use brushes and a commutator. Image courtesy of Clemson University.