Helical Worm Gear Units Southquip Industrial

Helical worm gear motor sew

Helical gears are the most often utilized kind of gear in gearboxes. Helical gears also provide a significant amount of thrust. Bearings are used to withstand this powerful force. Helical Gear Advantages When compared to worm gears or toothed wheels, the angled teeth function more slowly, resulting in more quiet and smoother gear performance.

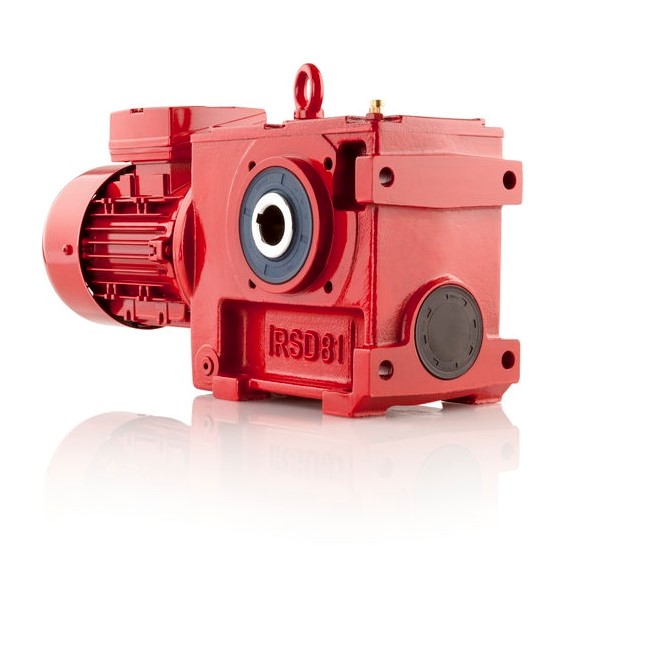

Helical Worm Gearbox SGR

1. Higher Efficiency. Helical gearboxes are known for their higher efficiency compared to worm gearboxes. The helical gear design allows for more teeth engagement, resulting in reduced friction and energy losses during power transmission. This translates to improved overall efficiency and lower energy consumption. 2.

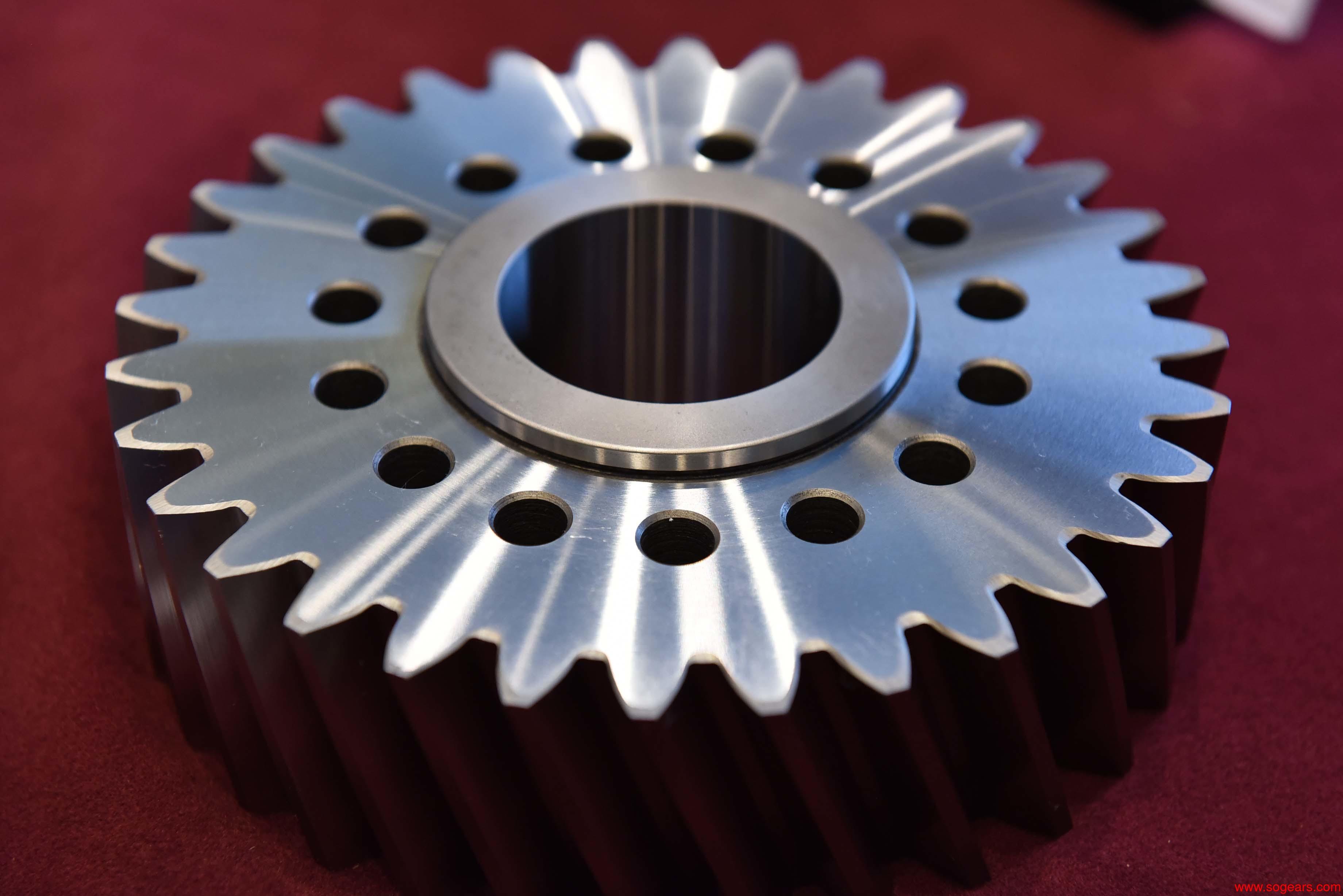

Helical Cast Iron NU Worm Gear, Rs 2000 /onwards Anand Gears ID 5019905288

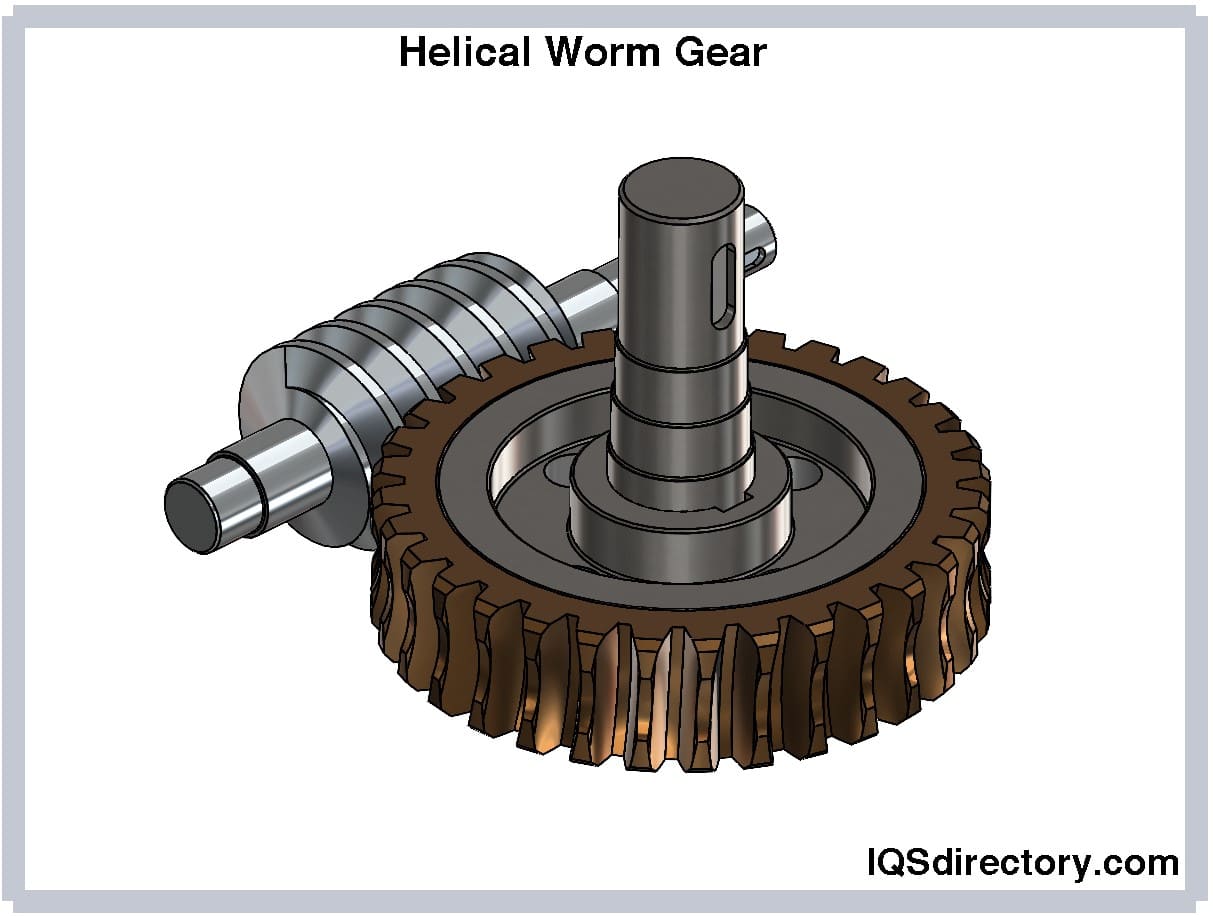

Definition of the Helical Gears Differences Between Worm and Helical Gear- Whether you are using servo gears, worm gears, or any other form of industrial gears, by improving torque output and regulating the direction of spinning, gears are an important part of many industrial motors and machinery.

Helical Cast Iron NU Worm Gear, Rs 2000 /onwards Anand Gears ID 5019905288

Helical bevel gearboxes are angular gearboxes where the output shaft of the gear unit turns 90 degrees in reference to the rotor shaft of the motor. Solid or hollow shafts are typical. Gearboxes with helical bevels, which may provide high power density and output torques, are appropriate for angular geared motor applications that need high.

Helical Worm Gear Units Southquip Industrial

SK02040.1 Helical Worm Gear Units - IE3 50/60Hz, Metric/Imperial TI60-0008. Product Information for IE3 - SK02040.1 Helical Worm Gear Units from NORD Gear Corporation. Download PDF German English US-English Products. UNICASE™ Worm Gear Units. SK 02040.1. Countries

Helical Worm Gear at best price in Howrah by D.S. Engineers ID 19156338962

Helical Vs. Worm Gearboxes. Helical gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. A worm gearbox may be a better option in low HP applications as it is much cheaper. A helical gearbox generally provides a better solution in applications requiring higher torque (for example, 10HP at a 30:1 ratio).

Helical vs Worm Gearboxes Differences, Advantages, and Disadvantages

Gear drive is preferably suitable for heavy power transmission over short distance. There are four basis types of gears, namely spur gear, helical gear, bevel gear and worm gear—each of them has different features and provides unique advantages over others. Differences between these four types of gear based on various factors are explained.

Spur Helical Worm Gear at best price in Coimbatore ID 5787665362

The Boston Gear 800BR series contains a broad selection of compact, heavy duty helical gear drives with long life performance features and simplified maintenance. The use of state of the art helical and worm gear combinations affords optimum performance fulfilling a wide variety of ratio requirements. Interchangeable with most major manufacturer's drives.

Helical Gear What Are They? How Do They Work? How to Manufacture Them?

Amrit Kumar. In this article, we will be study different types of gear and those are Spur Gear, Helical Gear, Double Helical and Herring Bone Gear, Crossed Helical Gears, and Worm Gear. At the end of the article you can download PDF of this articles. Gear is a Rotating Machine element that is having teeth which cut by the various Manufacturing.

brass helical worm gearManufacturer of Customized Machining

Your benefits Reduce noise as the helical-worm gearmotor minimizes noise pollution in the area surrounding your system thanks to its running smoothness. Increase efficiency because the gearmotor offers a high degree of efficiency thanks to its combination with a helical gear stage in the gear unit. Back to top Features Helical-worm gear units

R Series Coaxial Helical Gear Worm Gearbox Power Jack Motion

Helical-worm gear units: simple design, high efficiency The figure shows a gearmotor with a helical-worm gear unit The simple design makes for cost-effectiveness. The individual adjustment of torque and speed allows for space-saving installation of our helical-worm gear units.

gears Helical Worm Drive Engineering Stack Exchange

standardized as spur, heli-cal and bevel gearing. Several different 'systems' coexist in the marketplace, and each has its propo-nents. In the smaller gear-box sizes (less than 4-inch center distance), exterior and mounting dimensions have become 'standard' and users can easily interchange between brands.

Worms and worm gears tecscience

NEW: NORD's two-stage SK 02040 helical worm gear units have been redesigned as the new SK 02040.1 worm gear units. Made from high strength aluminum or die-cast aluminum, these units guarantee maximum strength and rigidity with low weight. They can be further protected with optional surface treatment such as the highly effective nsd tupH.

GS Series HelicalWorm Gear Motors ACORN

Hypoid gear motors provide higher efficiency, but for the best efficiency you should choose a helical bevel gear motor. The efficiency of a worm gear unit drops sharply with increasing gear ratio. With a gear ratio of 5 to 10, the efficiency is above 85%. If the ratio rises to 100, the efficiency of the worm gear unit is only 50%.

Helical Gears Versus Traditional Worm and Spur Gears

Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. 1. Spur gears are mounted in series on parallel shafts to achieve large gear reductions.

Casting Straight 42CrMo 50mm Steel Worm Gear Spur Helical Gear

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm wheel (which is similar in appearance to a spur gear ). The two elements are also called the worm screw and worm gear.